Robust conductive mesoporous carbon–silica composite films with highly ordered and oriented orthorhombic structures from triblock-copolymer template co-assembly

Citation

Song, L.; Feng, D.; Campbell, C.G.; Gu, D.; Forster, A.M.; Yager, K.G.; Fredin, N.; Lee, H.-J.; Jones, R.L.; Zhao, D.; Vogt, B.D. "Robust conductive mesoporous carbon–silica composite films with highly ordered and oriented orthorhombic structures from triblock-copolymer template co-assembly"

Journal of Materials Chemistry 2010,

20 1691–1701.

doi: 10.1039/b919400bSummary

To improve the robustness of carbon-based mesoporous films, a new preparation using silica was investigated. X-ray scattering results and electron microscopy are used to probe the improved structures.

Abstract

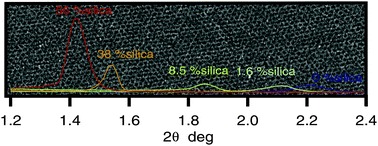

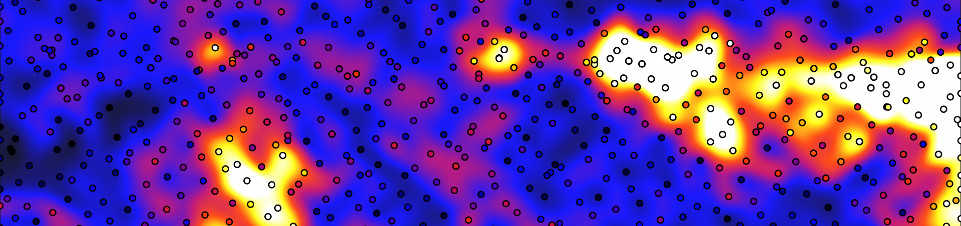

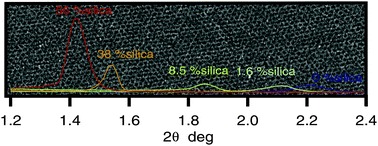

In this work, we describe a facile approach to improve the robustness of conductive mesoporous carbon-based thin films by the addition of silica to the matrix through the triconstituent organic–inorganic–organic co-assembly of resol (carbon precursor) and tetraethylorthosilicate (silica precursor) with triblock-copolymer Pluronic F127. The pyrolysis of the resol–silica–pluronic F127 film yields a porous composite thin film with well-defined mesostructure. X-Ray diffraction (XRD), grazing incidence small angle X-ray scattering (GISAXS), and electron microscopy measurements indicate that the obtained carbon-based thin films have a highly ordered orthorhombic mesostructure (Fmmm) with uniform large pore size (~3 nm). The orthorhombic mesostructure is oriented and the (010) plane is parallel to the silicon wafer substrate. The addition of silica to the matrix impacts the pore size, surface area, porosity, modulus and conductivity. For composite films with approximately 40 wt% silica, the conductivity is decreased by approximately an order of magnitude in comparison to a pure carbon mesoporous film, but the conductivity is comparable to typical printed carbon inks used in electrochemical sensing, ~10 S cm^-1. The mechanical properties of these mesoporous silica–carbon hybrid films are similar to the pure carbon analogs with a Young's modulus between 10 GPa and 15 GPa, but the material is significantly more porous. Moreover, the addition of silica to the matrix appears to improve the adhesion of the mesoporous film to a silicon wafer. These mesoporous silica–carbon composite films have appropriate characteristics for use in sensing applications.