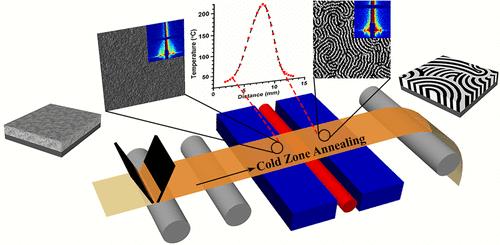

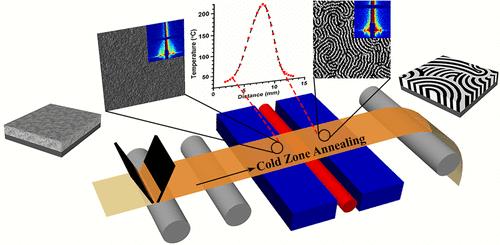

Through-thickness Vertically Ordered Lamellar Block Copolymer Thin Films on Unmodified Quartz with Cold Zone Annealing

Citation

Basutkar, M.N.; Samant, S.; Strzalka, J.; Yager, K.G.; Singh, G.; Karim, A. "Through-thickness Vertically Ordered Lamellar Block Copolymer Thin Films on Unmodified Quartz with Cold Zone Annealing"

Nano Letters 2017,

17 7814–7823.

doi: 10.1021/acs.nanolett.7b04028Summary

We exploit cold zone annealing to direct block copolymer lamellae into a vertical orientation.

Abstract

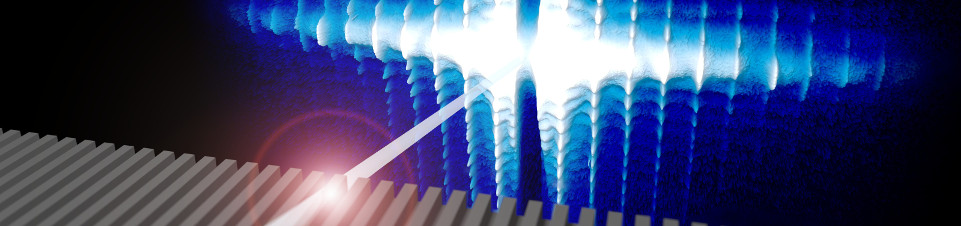

Template-free directed self-assembly of ultrathin (approximately tens of nanometers) lamellar block copolymer (l-BCP) films into vertically oriented nanodomains holds much technological relevance for the fabrication of next-generation devices from nanoelectronics to nanomembranes due to domain interconnectivity and high interfacial area. We report for the first time the formation of full through-thickness vertically oriented lamellar domains in 100 nm thin polystyrene-block-poly(methyl methacrylate) (PS-b-PMMA) films on quartz substrate, achieved without any PMMA-block wetting layer formation, quartz surface modification (templating chemical, topographical) or system modifications (added surfactant, top-layer coat). Vertical ordering of l-BCPs results from the coupling between a molecular and a macroscopic phenomenon. A molecular relaxation induced vertical l-BCP ordering occurs under a transient macroscopic vertical strain field, imposed by a high film thermal expansion rate under sharp thermal gradient cold zone annealing (CZA-S). The parametric window for vertical ordering is quantified via a coupling constant, C (= v gradT), whose range is established in terms of a thermal gradient (gradT) above a threshold value, and an optimal dynamic sample sweep rate (v ~ d/tau), where tau is the l-BCP’s longest molecular relaxation time and d is the Tg,heat – Tg,cool distance. Real-time CZA-S morphology evolution of vertically oriented l-BCP tracked along gradT using in situ grazing incidence small angle X-ray scattering (GISAXS) exhibited an initial formation phase of vertical lamellae, a polygrain structure formation stage, and a grain coarsening phase to fully vertically ordered l-BCP morphology development. CZA-S is a roll-to-roll manufacturing method, rendering this template-free through-thickness vertical ordering of l-BCP films highly attractive and industrially relevant.