Surface Morphology Diagram for Cylinder-Forming Block Copolymer Thin Films

Citation

Zhang, X.; Berry, B.C.; Yager, K.G.; Kim, S.; Jones, R.L.; Satija, S.; Pickel, D.L.; Douglas, J.F.; Karim, A. "Surface Morphology Diagram for Cylinder-Forming Block Copolymer Thin Films"

ACS Nano 2008,

2 2331–2341.

doi: 10.1021/nn800643xSummary

We provide a detail map of the effect of film thickness and annealing temperature on cylinder-forming block-copolymers. We also present evidence that residual solvent plays a role in biasing the orientation of block-copolymers during annealing.

Abstract

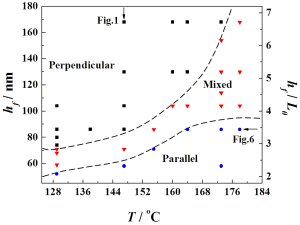

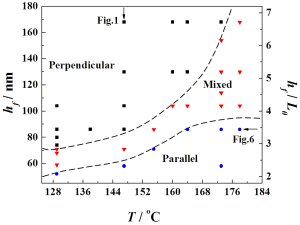

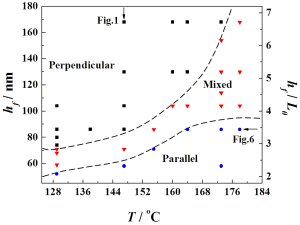

We investigate the effect of annealing temperature (T), film thickness (hf) on the surface morphology of flow coated films of a cylinder forming block copolymer, poly (styrene-block-methyl methacrylate) (PS-b-PMMA). Surface morphology transitions from a perpendicular to a parallel cylinder orientation with respect to the substrate with increasing hf are observed in these model ‘frustrated-interaction’ films where the substrate interaction is preferential for one of the blocks (PMMA) and nearly neutral for the other interface (polymer-air). In these films a transition occurs from cylinders oriented parallel to the substrate to a mixed or ‘hybrid’ state where the two orientations coexist followed by a transition to cylinders oriented perpendicularly to the polymer-air interface for larger hf. The characteristic values of hf defining these surface morphological transitions depend on T and we construct a surface morphology diagram as a function of hf and T. The surface morphology diagram is found to depend on the method of film formation (flow coated versus spun cast films) so non-equilibrium effects evidently have a large effect on the surface pattern morphology. In particular, the residual solvent within the film (quantified by neutron reflectivity measurements) in the context of physics of glass-formation can have a large effect on the surface morphology diagram.